Commercial Wooden Boat Plans for High-End Production

The creation of high-end, commercially viable wooden boats requires meticulous planning and execution. This necessitates not only skilled craftsmanship but also robust, well-designed plans that account for production efficiency, material optimization, and the consistent delivery of superior quality. This document details the key considerations in developing commercial wooden boat plans geared towards high-volume, high-quality production. The focus will be on streamlining processes, minimizing waste, and maximizing the return on investment for a successful business venture.

I. Design Considerations for High-Volume Production

The design phase is paramount. A design optimized for mass production differs significantly from one intended for a single, bespoke build. Efficiency must be prioritized from the outset. This section will explore crucial design elements critical to achieving both quality and scalability.

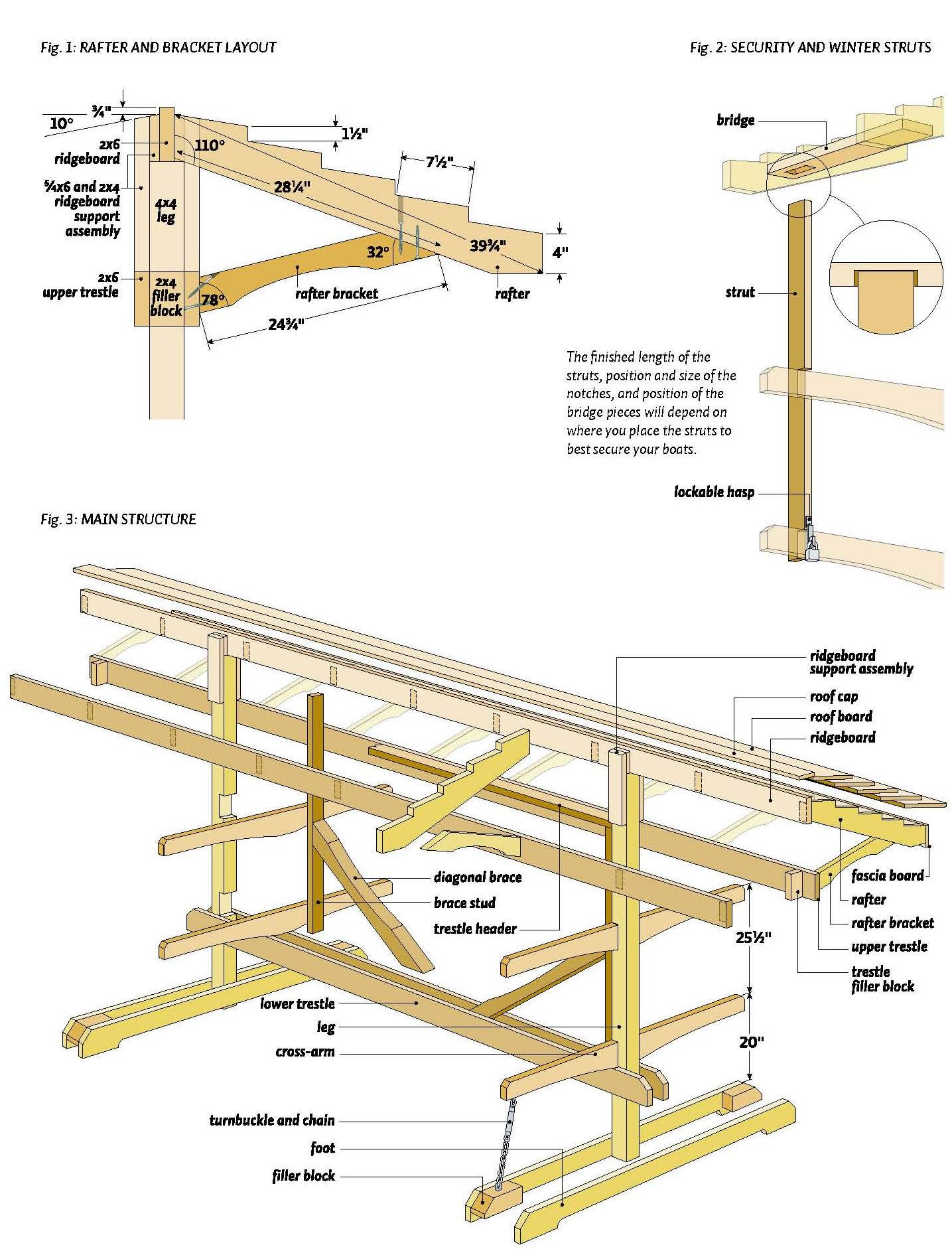

A. Standardized Components and Modular Design

Employing standardized components reduces complexity and speeds up assembly. The boat's design should be broken down into modular sections that can be pre-fabricated and assembled efficiently. This modular approach allows for parallel construction, significantly reducing overall build time. For example, bulkheads, frames, and seating units can be produced in batches, minimizing individual crafting time and ensuring consistency.

B. Material Selection and Sourcing

The choice of wood species significantly impacts both cost and production. Select readily available, durable, and relatively easy-to-work-with woods that meet the required strength and aesthetic standards. Establish reliable sourcing channels to guarantee consistent material supply and quality. This also helps manage costs effectively.

C. Simplification of Joinery and Construction Techniques

While maintaining structural integrity and high-quality finish, simplifying construction techniques is crucial for efficient production. This involves selecting joinery methods that are both strong and relatively quick to execute, minimizing the reliance on highly specialized skills.

II. Production Process Optimization

Efficient production flow is essential for maximizing output and minimizing costs. Careful planning of the workflow and the utilization of appropriate technologies are key components of a successful commercial operation.

A. Workflow Design and Lean Manufacturing Principles

Implement lean manufacturing principles to eliminate waste and optimize the production process. This involves analyzing each step of the workflow, identifying bottlenecks, and implementing improvements to streamline the process. Visual management tools, such as Kanban boards, can be employed to manage inventory and track progress.

B. Automation and Technology Integration

The integration of appropriate technology can significantly improve efficiency and quality. While some aspects of wooden boat construction remain artisanal, automation can be incorporated in areas such as cutting, shaping, and finishing. This increases consistency and reduces labour costs.

C. Quality Control and Inspection

Rigorous quality control measures are essential to maintaining a high standard of craftsmanship. Regular inspections at various stages of the production process will ensure that defects are identified and addressed early on, preventing costly rework and ensuring customer satisfaction.

III. Market Analysis and Business Strategy

Even with superior designs and efficient production, a successful business requires a strong understanding of the market and a well-defined business strategy. Thorough market research, competitive analysis, and a clear understanding of target customers are crucial for long-term sustainability.

By carefully considering the design, production, and market aspects outlined above, businesses can develop commercial wooden boat plans capable of delivering high-end, consistent quality, and a strong return on investment in the competitive marketplace.